Difference between revisions of "Site Maintenance"

m (→Gas Analysis) |

m (→Equipment) |

||

| Line 689: | Line 689: | ||

Permission to enter data into this tab is set in Admin/User Role Management under the Daily Section. | Permission to enter data into this tab is set in Admin/User Role Management under the Daily Section. | ||

| − | + | ||

| − | Air Pollution Control Equipment Section: | + | <u>'''Air Pollution Control Equipment Section:'''</u> |

| − | Radial check buttons specify whether a combustor or vapor recovery units exist on site. Selecting one of these types causes PumperX2 to include the APCE reporting group on the production tab, assuming the | + | |

| − | Other Equipment Section: | + | Radial check buttons specify whether a combustor or vapor recovery units exist on site. Selecting one of these types causes PumperX2 to include the APCE reporting group on the production tab, assuming the APCE group is included in the assigned layout for PumperX2. |

| − | To add an item of equipment to a site, first a defined class of equipment | + | |

| − | Equipment entered in the Other Equipment section serves two distinct roles within AnalystX2. The first role allows capture of operational data associated with the equipment for use in internal and external reports. The second role captures fuel usage data that may be applied directly to the well the equipment is attached to or used in an allocation to provide for adding back production volumes that do not exist at the source. | + | The entry group contains equipment status (on/off) and whether an inspection is recorded. Optionally a weekly inspection requirement can be specified. |

| − | Equipment may be defined and associated to a specific site in this tab. Equipment items can be defined for any class of site. To allow for segregating equipment within PumperX2 there is a specific class (Equipment) that can contain only equipment items. This allows you to create 'stops' for the pumper that are distinct from other sites that appear in the selection tree for a route | + | |

| − | + | <u>'''Other Equipment Section:'''</u> | |

| + | |||

| + | To add an item of equipment to a site, first a defined class of equipment must exist in [[Equipment Definitions]]. | ||

| + | |||

| + | Equipment entered in the Other Equipment section serves two distinct roles within AnalystX2. | ||

| + | |||

| + | The first role allows capture of operational data associated with the equipment for use in internal and external reports. | ||

| + | |||

| + | The second role captures fuel usage data that may be applied directly to the well the equipment is attached to or used in an allocation to provide for adding back production volumes that do not exist at the source. | ||

| + | |||

| + | Equipment may be defined and associated to a specific site in this tab. Equipment items can be defined for any class of site. | ||

| + | |||

| + | To allow for segregating equipment within PumperX2 there is a specific class (Equipment) that can contain only equipment items. This allows you to create 'stops' for the pumper that are distinct from other sites that appear in the selection tree for a route. | ||

| − | + | Click Add and the New Equipment Period window open > Enter a name for the equipment item and specify it's class and start date, (format MM/DD/YYYY) > Click 'Save'. | |

| − | The Equipment Setup window will | + | |

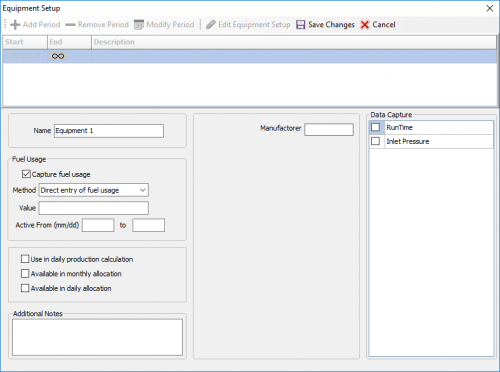

| + | The Equipment Setup window will allowing to input the equipment information: | ||

| + | |||

| + | [[File:Equipment Setup Page.png|500px]] | ||

Five sections of the panel define Name, Fuel Usage, Notes, Properties and Capture. | Five sections of the panel define Name, Fuel Usage, Notes, Properties and Capture. | ||

Revision as of 22:56, 16 December 2019

Contents

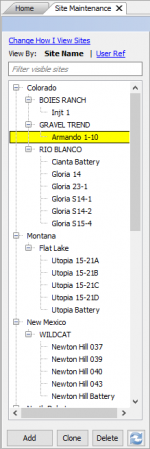

Vewing and Adding Sites

|

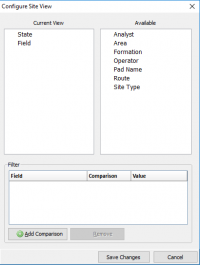

As sites are created they will be stored in a tree view to the left. When you first enter site maintenance the tree view will be blank. To add a site see Adding a Site, to clone an existing site see Cloning a Site, to delete an existing site see Deleting a Site. Click on a Site to view/edit. Clicking on another Site displays the new Site in the same relative screen position. If a change was made the 'Save changes to site?' prompt will display prior to moving to the new Site. This navigation enables quick review of Site information in a focused manner. Selecting Change How I View Sites will open the Configure Site View window: The default layout will be displayed in State\Field order. To select an available option click and drag it to the current view box. There is also an option to Add a Comparison from a field drop-down list that will use a comparison, of 'equals' (=) or 'not-equal'(<>), to any given value. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

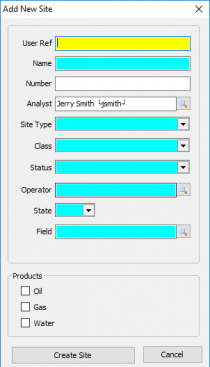

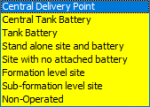

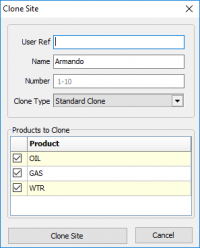

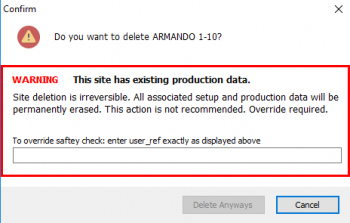

Adding a SiteTo add a site select the Add button under the tree view. This will bring up the window to the left and required the following inputs. When Complete click Create Site to create the base Site Information and access to the General Site Maintenance tab. Cloning a SiteTo Clone a Site, select the Site to be cloned and click Clone. The following window displays: Clone Type The Clone Type drop down selections are Standard Clone and Clone to Disposal Site. Cloning to a disposal site will bring over all the same info but change the Site type, Class, and Status. This can be modified in the General tab. Deleting a SiteTo Delete a site, select the Site and click Delete. The following warning is displayed: If the site has no production behind it it will delete it. If it does you will have to do the override by entering the user_ref.

Site Maintenance TabsGeneral

ProductsProducts types are Oil, Condensate, Gas or Water. All production volumes are associated to a product. Sites can have an unlimited number of Products (to include Products of the same type) to accommodate the various internal data capture and regulatory reporting requirements. Each Product has a separate information page accessed by clicking the Product. When creating products, the order of creation will determine what order the Production Entry screens will appear. Oil

Gas

Water

LocationThe Location tab allows defining the physical location of a site within a state. The panel is divided into five sections to describe the surface and bottom hole locations for the site:

CompanyThe Site Maintenance Company tab allows the entry of company specific information such as Working Interest, Net Revenue Interest (NRI), Office, District, Engineer, etc. for a site. Clicking on the Company tab displays the panel below. Permission to add, edit or delete data in this panel is set in the Admin / User Role Management permissions section. Subsection Company

Dollars To Date

Info

Xref Although there are many data items in the primary input pages that can be used to control or sort against, there are always "other" identifiers that don't fit the "standard" data items. Xref section of the Site file allows the input of such items. X ref are alphanumeric items used as references for moving data between AnalystX2 and a Third-Party software, examples being Bolo and Aries. The first 6 items of the list are standard items that most companies use for data exchanges. The Accounting item would denote the internal ID of this site in a company accounting system. The same principal applies to the terms Economics, Marketing, Other Operator ID, and the two miscellaneous terms. If used, the Accounting data position MUST refer to the same thing in all sites. If required, each of the items in this section can be renamed by clicking on the cog icon to the right of the input box. The other 9 identifiers, User Xref(1-9), may be used as reporting or control items and can be changed with the cog icon. Any item name change will change that name for ALL sites in the data base. An example being: you can't use User Xref 1 for a work over date in one well site and as something else in another site. RegulatoryThe Regulatory tab is a depository for critical information used for State and Federal reporting. This panel contains five sections: general, state, federal lease/MMS Agreement#, Well count, and Federal. The order of data input is controlled only by what data is required for the site. State and Federal site Identification numbers, Permit numbers, Federal Lease/ Agreement numbers are inserted here. These critical numbers are required for creating State and Federal reports. The General Section a 14 digit API number, is required for State reporting. The Lease Name or Number is a requirement for certain, but not all state agencies. The State Section if the site is not reported to any state agency, these boxes may be left blank. The Well Count Section is used only for Montana reports. However, many users, use this panel to account for the number of wells included in a site allocation. The Federal Section a Federal Well Code is currently used only for Offshore reports. The Interval Code is a three-character code related to the number of open intervals in a well. An example of the interval code is S01.

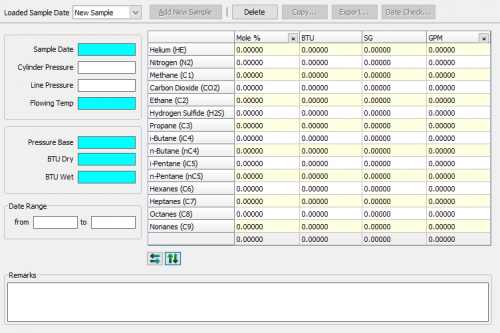

If a well is drilled on a Federal lease, the Federal Agreement number or Federal Lease number is required. Because Federal lease numbers can change over time, all Federal Agreement or Federal Lease numbers related to a site or used on the Federal OGOR report, must be recorded in the Federal Agreement number box. To add a new federal lease: Click add > Type in a new lease name or use the spy glass icon to find the name of an existing federal lease > Select the type of lease FED or MMS > Add a start period > click OK. The new lease agreement appears in the box. If a site is to be reported under a new lease, you must end date the active lease before adding the new lease. Highlight the current lease > Click Edit > Add a stop date > Click OK >Click Add to enter a new lease and use a start date > The day after the end date > Click OK. By maintaining leases using effective date, the regulatory reporting process will automatically take care of the stock transfers when the report is filed. After clicking OK the site is using the second Federal Lease Number and complies with Federal regulations for the site. Click Save Changes to record the new data in the regulatory tab. Gas AnalysisThe Gas Analysis tab allows entering gas composition data, ie. the amount of methane, carbon dioxide, nitrogen, etc as determined by a sample analysis. Permission to add, edit or delete data is set in Admin / User Role Management. Gas analysis data may be entered into a site file in two ways: via direct entry or by an external file upload. To see or enter data > Select the desired site > Then click on the Gas Analysis tab > Click Add New Sample > The following display will appear: The 5 blue highlighted boxes are required fields. Gas analysis information can vary widely based on the needs of the company. Some operators require everything while others need only data through C5 and everything else is listed as C6. In most cases, the Mole % value is the only value that is required. BTU and Specific Gravity (SG) values may not be needed. GPM (gallons per million cubic feet) can be calculated based on industry standards or it could be manually entered. AnalystX2 will calculate GPM base on industry standards. Click the small Mole % values are decimal and do not always add up to 100%. The The Date Range items allow you to specify the date range for applying the gas analysis. The other buttons at the top of the screen allow deleting an existing analysis, copying an analysis to another site, exporting the data in an XLS file format, or checking the dates for which the samples were entered. EquipmentThis tab allows entering three types of data; entering whether or not any Pollution Control Equipment (combustor or vapor recovery) exist for a site, indicating whether or not a weekly inspection is reported and what equipment will be assigned to the site. Permission to enter data into this tab is set in Admin/User Role Management under the Daily Section.

Radial check buttons specify whether a combustor or vapor recovery units exist on site. Selecting one of these types causes PumperX2 to include the APCE reporting group on the production tab, assuming the APCE group is included in the assigned layout for PumperX2. The entry group contains equipment status (on/off) and whether an inspection is recorded. Optionally a weekly inspection requirement can be specified. Other Equipment Section: To add an item of equipment to a site, first a defined class of equipment must exist in Equipment Definitions. Equipment entered in the Other Equipment section serves two distinct roles within AnalystX2. The first role allows capture of operational data associated with the equipment for use in internal and external reports. The second role captures fuel usage data that may be applied directly to the well the equipment is attached to or used in an allocation to provide for adding back production volumes that do not exist at the source. Equipment may be defined and associated to a specific site in this tab. Equipment items can be defined for any class of site. To allow for segregating equipment within PumperX2 there is a specific class (Equipment) that can contain only equipment items. This allows you to create 'stops' for the pumper that are distinct from other sites that appear in the selection tree for a route. Click Add and the New Equipment Period window open > Enter a name for the equipment item and specify it's class and start date, (format MM/DD/YYYY) > Click 'Save'. The Equipment Setup window will allowing to input the equipment information: Five sections of the panel define Name, Fuel Usage, Notes, Properties and Capture. Name: The display name of the equipment, used where ever the equipment is referenced. Fuel Usage: Reports fuel usage : yes, click the check box and select the method of data capture parameters; no, continue without checking box. The Direct Entry Of Fuel Usage means that you will manually enter some value every day or month. Acquire From Defined Meter means that you have defined a separate gas meter to record the fuel usage for this piece of equipment. The Value item enters a value to be used for any of the Fixed items listed above. Acquire From Defined Meter means the meter used to measure the fuel used as setup under the Gas product. The Active From items allow you to specify the production dates for which this equipment setup is functional. The remaining items on this screen are the Equipment Property items and the equipment Data Capture Items setup with the Equipment Definitions. Since you may setup several data capture items for an equipment class but may need only certain ones for a single piece of equipment you will need to place a check mark next to the data items you want to capture for this one piece of equipment. ProductionThe Production tab displays two simple charts showing monthly and daily data. The monthly chart shows the complete monthly production history while the daily charts shows only the last 30 days of production. To the right of each chart are the production values. These screens however, are for review purposes only. For a more detailed examination of production history, use PDV in the AnalystX2 . Data for Monthly and Daily charts may be erased from display by using the Delete buttons. The data will not be removed from the database when using these delete buttons. ForecastManually input data to calculate a forecast of production.

To access the Forecast tab, in AnalystX2 click Site, then Site Maintenance. Highlight the desired site. Then Click the Forecast tab. In this panel, you can import or manually enter monthly forecast values and quickly view a graph of the monthly data. There are three main parts to the panel: the chart on the lower right, the monthly input data on the left and Options to choose whether the chart is to be Cartesian or logarithmic. On the top row, you can select a Forecast type. These forecast types are previously saved charts. To create a new Forecast type, click types. When the window opens, click New type in the lower left corner. The Forecast Type Definition panel appears. Input a name. The description is optional. In the Daily Forecast Derivation Method, select one of the two options: divide the monthly value by the number of days in the month or use a fixed divisor. The fixed divisor by default is 30 days per month, however any required number may be used. Next select whether or not you want the forecast to appear in the PumperX2 display by checking the box. Types may be deleted using the Delete button in the lower left corner. When done, Click Save Changes. To close the panel, click the X in the upper right. The panel on the left is ready for manually entering data. You can enter as many months as needed. When done Click Save Changes to produce a Forecast graph. In the display, Green represents oil, red equals gas, and blue represents water. To import forecast data. Click the Import Button and the following screen appears. At the top of this display are the import control items. Xref Type means "What item in the site record is used as the import control?" Click the drop-down arrow to view the possible control items. For example, you could use the Accounting id number or the economics id number as possible control items. Next choose the forecast type by using the Forecast type dropdown menu. If needed, you can also create a new type by using the Types button. Import file designates the location and name of the import file. Import Files can be either XLS, CSV, or TAB Delimited.

The sample files indicate that we want to import forecast data for two sites (Sample1 and Sample2) and both for the period 1/2016-3/2016. Each row of the file must have a well identifier and period defined however, you can include as many sites and periods as required. The following is a workflow example of how to import a forecast file. Use the Xref dropdown menu to Specify the well identifier type. Click the dropdown menu to Specify the forecast type. If your file contains a header row, Check the 'Ignore first row' box. In the Import file box use the icon on the right to navigate to the import file. Select the file. Click 'Scan File' to examine the file. When the scan completes, review the data for any error messages. If no errors are found, click 'Start Import' to initiate the import. Close the Import Forecast tab. The imported data may be displayed. If not choose, the correct Forecast Type DiaryThe Diary section is a text based panel for users to add occasional or daily comments and notes regarding the highlighted site.

Copyright © 2019 by PRAMS Plus LLC. All Rights Reserved. |