Global Settings

Global Settings sets preferences and overrides the default program behavior in various areas of the PRAMS Plus suite.

◄ Admin

Contents

General Settings

- Use uncorrected ticket volumes in daily calculation

- The default program behavior is to use the corrected (60°F and BS&W) crude oil run ticket volume when calculating daily production. To override the default behavior check this setting to use uncorrected (apparent sales).

- Round daily oil production for color-cut tanks

- The default program behavior is to calculate and display volumes to 2 decimal places (i.e. 52.45). To override the default behavior check this setting and all volumes will be rounded to the nearest whole volume (52 versus 52.45).

- Require users to use cryptographically strong passwords

- Check this setting to require cryptographically strong passwords. PRAMS defines cryptographically strong as 8 or more characters in length and any 3 of the following characteristics, lowercase and uppercase alphabetic characters, numbers or symbols. The default program behavior does not enforce strong passwords.

- Require remark if down-code is specified in PumperX2

- Check this setting to require the user to enter a Remark on days that a down-code is entered. The default program behavior does not require a Remark.

- Use questionnaire to determine if Enhanced AVO Inspection is required

- Will ask a short prompt to remind the pumper to do the inspection if required.

- Set ticket date one day back from entry date in oil ticket entry

- When entering a ticket in pumperX2 rather than default the ticket date to the entry date it will set the ticket date (used for reporting) one day back. Can help with end of month tickets.

- Do not include water tickets on oil tanks in production in RtChex import

- Excludes water tickets if assigned to an oil tank when the import runs.

- Hide entered water column if tank or meters exist

- By default if a water product exists on a site and is not hidden a 'Enter Prod' column will appear allowing for water entry. If checked it will remove this column to avoid confusion.

Daily Allocation

- Number of days to review for the daily allocation

- The daily allocation routine can be set to review data back as many days as desired and allocate new or changed data.

- The more days to review, the longer the process takes to complete.

APEN Entry Requirements

- Enable manual entry rules for air pollution control equipment

- The program is defaulted to 'on\off' prompt for APCE 'up\down' time.

- Checking this changes the 'on\off' to a Time On and Time Off inferring the actual 'up\down' time is knowable.

PumperX2 - User Defined Columns

- If you have daily field data-points to be captured\input that PRAMS does not provide for in the base program, 9 user definable column headings can be added to the PumperX2 input page.

- These are data input items only. No calculations or validation will be carried out on these items.

- Editing User Defined Columns

When a column has been named a data type or a dropdown list can be added allowing flexibility in PumperX2.

Start by naming a column and then selecting the "Edit User Defined Column Options" button.

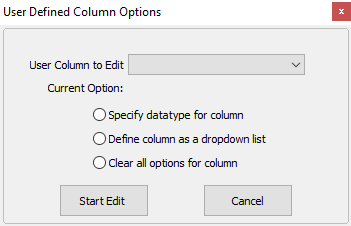

When opened select the column in the "User Column to Edit" dropdown.

Next select a radio button for datatype or dropdown.

- If data type has been selected you can chose one of the following

- Allow any data type

- Text

- Integer

- Decimal

- Y/N (Yes or No)

- Date

- Time

- If dropdown has been selected a screen will appear with handles on the left-hand side and a blank space to the right of each handle.

Enter in the text options in the blank space to create a dropdown list. If need be the handles can be click and dragged to move the order around.

Once saved to see in PumperX2 either close and reopen the program or use the reload button, when in direct mode. For filed users they most likely will need to preform a sync. Additionally when saved an acronym will show next to the column to specify the data type or dropdown.

To edit simply repeat the process, all data is saved so you can see what the type or drop down options are upon edit.

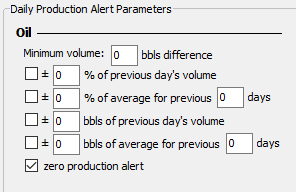

Daily Production Alert Parameters

- Used to define daily production variance alert thresholds used in certain reports.

- Variances thresholds can be distinctly set by product (oil, gas or water) and by time period (day to day or day to 7 day average) by absolute volume or percentage. A zero-production alert is also available.

In order to use the Production Alerts, at least one of the following need to be selected:

Gas Analysis - Mole % Balance

- The program requires the Mole% to equal 100%. If the mole percentage of the Gas Sample being entered or imported does not total exactly 100% the rounding difference is added to Methane by default.

- To override the default select the component to absorb the rounding.

BOE Factor

- Enter the factor to be used in any BOE conversions displayed or reported in the program. Industry standard is 6 to 1. Gas MCF volumes are converted using the factor and added to the Oil product volumes to arrive at BOE.

Pressure Warning

- Enter in a pressure that will alert in the Line Pressure Alert task. When in the task set the variant to be above or below the given number.

Copyright © 2026 by PRAMS Plus LLC. All Rights Reserved.