Difference between revisions of "Daily Allocation Setup"

m (→Adding an Allocation.) |

m (→Gas Test) |

||

| (15 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

''Set up sites and products to be allocated and the order in which the allocation or allocations will be performed.'' | ''Set up sites and products to be allocated and the order in which the allocation or allocations will be performed.'' | ||

| + | ---- | ||

| + | ◄ [[Daily Processes]] | ||

| − | ===<u>'''Main Screen'''</u>=== | + | ===<u>'''Main Allocation Screen'''</u>=== |

To begin select Daily Processes > Daily allocation Setup, the following screen will open: | To begin select Daily Processes > Daily allocation Setup, the following screen will open: | ||

| Line 24: | Line 26: | ||

|} | |} | ||

| − | ===<u>'''Adding an Allocation.'''</u>=== | + | ====<u>'''Adding an Allocation.'''</u>==== |

{| | {| | ||

| Line 39: | Line 41: | ||

Any product that is in this screen, does not have an allocation yet and is available to allocate. | Any product that is in this screen, does not have an allocation yet and is available to allocate. | ||

| − | After you select a product you will be prompted to input in a start date and you can also add in a description for the new period. Make sure it matches the other products if they come on at the same time. | + | After you select a product you will be prompted to input in a start date and you can also add in a description for the new period. |

| + | |||

| + | Make sure it matches the other products if they come on at the same time. | ||

When the date info has been added then the target selection screen will appear: | When the date info has been added then the target selection screen will appear: | ||

| Line 46: | Line 50: | ||

To add in sites select the site on the right using the filter to find it and click and drag over or double click. Shift and Ctrl select is also allowed here. | To add in sites select the site on the right using the filter to find it and click and drag over or double click. Shift and Ctrl select is also allowed here. | ||

| + | |||

| + | Next add in a allocation code to determine a Test Derivation Method. A full list can be seen in the next section of this page for reference. | ||

A feature of adding in other allocations for a site is that if one product has been added in then the others will be able to automatically fill in the matching targets. | A feature of adding in other allocations for a site is that if one product has been added in then the others will be able to automatically fill in the matching targets. | ||

You will also be able to do this in monthly allocation setup, this is why is recommended to start your daily first. | You will also be able to do this in monthly allocation setup, this is why is recommended to start your daily first. | ||

| + | |||

| + | When all targets have been added in then save your changes. | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | ===<u>'''Test Methods'''</u>=== | ||

| + | |||

| + | In order for you allocation to work it need extra information to go off of based on what test method is used. | ||

| + | |||

| + | Here are the definitions that can be used: | ||

| + | |||

| + | ====<u>Oil Test</u>==== | ||

| + | |||

| + | {| class= "wikitable" style="width: 100%;" | ||

| + | |+ '''Oil Test Methods''' | ||

| + | |- | ||

| + | |style="width: 10%"|T - Fixed Ratio | ||

| + | |Locates the most recent daily test value and applies it as a fixed ratio within the allocation. This is the most common method used. To learn how to add a daily test [[Site_Maintenance#Adding_Test_Data|click here]]. | ||

| + | |- | ||

| + | |H - Hours On X Test | ||

| + | |Uses the most recent daily test value and calculates a new value by taking the test value divided by hours on times 24 hours: ((test value/hours on)*24) | ||

| + | |- | ||

| + | |D - Define Value | ||

| + | |A special allocation method that uses whatever value is listed as the entered production for a day is to be kept whole and all other wells in the allocation share whatever production in the source file remains. | ||

| + | |- | ||

| + | |E - Gas Production | ||

| + | |The current day’s gas production is used for the test. When using this method you must make sure that the gas production records exist, either by entry or proper ordering of the products in the allocation. A gas test value will be zero if gas records are absent. | ||

| + | |- | ||

| + | |3 - Test is Water Production | ||

| + | |The current day's water production is used for the oil test. Requires that water is defined to be allocated prior to oil in source. | ||

| + | |- | ||

| + | |J - Custody Meter | ||

| + | |This method retrieves the sum of the current day and product's oil meters on the well and applies that volume as the allocated volume as long as the sum of this value plus any other products in the allocation that use methods D, J, M or R is less than or equal to the total volume in the source. If the source is less than the total amount it will receive a proportional amount based on it's relative value within the other defined types. Nothing will be allocated if an oil test value is absent. | ||

| + | |- | ||

| + | |L - LACT Meter | ||

| + | |The sum of the oil LACT meters for the current day and product are used as the test value. Zero will be the test value used if oil values are absent. | ||

| + | |- | ||

| + | |5 - LACT Meter Minus Load Oil | ||

| + | | This method retrieves the calculated LACT meter production and uses it as its base test value. If there is no meter volume the most recent test value is used. The sum of any non-calc oil meters is retrieved and the test is reduced by that amount. | ||

| + | |- | ||

| + | |O - Gas Yield | ||

| + | |This method calculates the test value by retrieving the most recent test value and the sum of the gas production for the day. The Gas Yield method derives the test value using the formula: (TEST/1000) x GASPROD. When using this method be sure to check that the gas product(s) are either entered or allocated previously. | ||

| + | |- | ||

| + | |P - Hrs x Test w/Fixed Test | ||

| + | | This method is similar to type H, but treats test as mandated volume if site in test for allocation date. | ||

| + | |- | ||

| + | |R - Turbine Meter | ||

| + | |This method retrieves the current day's oil test value and applies that volume as the allocated volume as long as the sum of this value plus any other products in the allocation that use methods D, J, M or R is less than or equal to the total volume in the source. If the source is less than the total amount it will receive a proportional amount based on its relative value within the other defined types. Zero will be the test value used if oil values are absent. | ||

| + | |- | ||

| + | |S - LACT w/CI+Sales | ||

| + | |This method is used for battery to pad allocations. Source is allocated using LACT meters then the pad sales and then change in inventory is added back in. | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | ====<u>Gas Test</u>==== | ||

| + | |||

| + | {| class= 'wikitable' | ||

| + | |+ '''Gas Allocation Methods Available''' | ||

| + | |- | ||

| + | |style="width: 10%"|T - Fixed Ratio | ||

| + | |Locates the most recent daily test value and applies it as a fixed ratio within the allocation. This is the most common method used. To learn how to add a daily test [[Site_Maintenance#Adding_Test_Data|click here]]. | ||

| + | |- | ||

| + | |H - Hours On X Test | ||

| + | |Uses the most recent daily test value and calculates a new value by taking the test value divided by hours on times 24 hours: ((test value/hours on)*24) | ||

| + | |- | ||

| + | |D - Define Value | ||

| + | |A special allocation method that uses whatever value is listed as the entered production for a day is to be kept whole and all other wells in the allocation share whatever production in the source file remains. | ||

| + | |- | ||

| + | |A - Hrs x Test w/GL Removed | ||

| + | |This method derives the test by first resolving the hours on x test and then removes the gas lift volume from the test prior to allocation. | ||

| + | |- | ||

| + | |B - Check Meter (Site) | ||

| + | |This method uses the sum of all check meters for all gas products on the target site for the test value. If no check meter volumes exist the process will look for the most recent daily test value. | ||

| + | |- | ||

| + | |C - Check Meter | ||

| + | |This method sums the meter volumes on the current product and day where the meter is defined with a disposition type 'Check Meter'. The Check Meter methods will default to using the most recent daily gas test as a fixed ratio if gas records are absent. | ||

| + | |- | ||

| + | |F - Hours x Test w/Gas Lift Recalculation | ||

| + | |This method starts by following the same process as type H but recalculates the production after the allocation is complete by deducting any gas lift. The volume for the gas lift is determined by adding up the meter volumes for the current day and product where the disposition specified is 'Gas Lift'. | ||

| + | |- | ||

| + | |G - Gas Oil Ratio | ||

| + | |The test is determined by resolving the most recent daily gas test which is the ratio to use and the finding the total oil production for the day and applying the formula: OILPROD x RATIO. When using this method ensure that the oil production is either entered or allocated prior to the gas product. | ||

| + | |- | ||

| + | |I - Check - Lift | ||

| + | |This method sums the gas check meters on the site and reduces that amount by the amount of gas lift meter volumes to calculate a volume for the test value. If no check meter values exist the most recent 24 hour test is used. | ||

| + | |- | ||

| + | |K - Oil Production | ||

| + | |The current days oil production is used for the test. When using this method you must ensure that the oil production records exist, either by entry or proper ordering of the products in the allocation. If no oil records are found the test value used will be zero. | ||

| + | |- | ||

| + | |M - Meter Test | ||

| + | |This method retrieves the sum of the current day's gas check meters for the product and applies that volume as the allocated volume as long as the sum of this value plus any other products in the allocation that use methods D, J, M or R is less than or equal to the total volume in the source. If the source is less than the total amount it will receive a proportional amount based on it's relative value within the other defined types. If check meter records do not exists for the current day then it will be allocated zero. | ||

| + | |- | ||

| + | |N - Gas Lift Test | ||

| + | |This method retrieves the sum of active gas lift meters to use as the test value and then removes the gas lift from the allocated gross production after the allocation is complete. | ||

| + | |- | ||

| + | |P - Hrs x Test w/Fixed Test | ||

| + | |This method is similar to type H, but treats test as mandated volume if site in test for allocation date. | ||

| + | |- | ||

| + | |Q - Metered Gas in Gas Lift Allocation | ||

| + | |This method is designed to work explicitly with other products on the well defined as type 'F' to allow wells to be included in the allocation that are only used to reduce the source volume from the return gas meter. It retrieves the sum of the custody meter volumes on the product as the test value. Updates are not made to product records with Metered Gas in Gas Lift Allocation. | ||

| + | |- | ||

| + | |S - Sum Gas From Targets | ||

| + | |If all gas target products use method S then create/update meter and product of source product with the sum of the targets. Source product must have a sales meter. | ||

| + | |- | ||

| + | |V - Hrs x Test w/Fixed Test (GL) | ||

| + | |This method defaults to hours x test unless a test exists for the day, then becomes mandated value. Any gas lift is removed from the test prior to allocation. | ||

| + | |- | ||

| + | |U - Gas Lift Test | ||

| + | |This method retrieves the sum of active gas lift meters to use as the test value. | ||

| + | |- | ||

| + | |X - Sales Meter Sum with Source Update | ||

| + | |This method sums up the sales meters on the targets and creates a source record to allow allocation of the combined sales from multiple products. Source product must have 2 gas products (Sales/Sum). | ||

| + | |- | ||

| + | |1 - Hrs x Test - Gas Lift | ||

| + | |This method first gets a base test using method H (hours on x test) then removes the sum of the gas lift meters to create the final test to be used. | ||

| + | |- | ||

| + | |2 - Check - Buyback | ||

| + | |This method derives a test value by reducing the sum of the check meter volume by the sum of the buyback meter volumes. | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | ====<u>Water Test</u>==== | ||

| + | |||

| + | {| class= 'wikitable' | ||

| + | |+ '''Water Allocation Methods Available''' | ||

| + | |- | ||

| + | |style="width: 10%"|T - Fixed Ratio | ||

| + | |Locates the most recent daily test value and applies it as a fixed ratio within the allocation. This is the most common method used. To learn how to add a daily test [[Site_Maintenance#Adding_Test_Data|click here]]. | ||

| + | |- | ||

| + | |H - Hours On X Test | ||

| + | |Uses the most recent daily test value and calculates a new value by taking the test value divided by hours on times 24 hours: ((test value/hours on)*24) | ||

| + | |- | ||

| + | |D - Define Value | ||

| + | |A special allocation method that uses whatever value is listed as the entered production for a day is to be kept whole and all other wells in the allocation share whatever production in the source file remains. | ||

| + | |- | ||

| + | |E - Gas Production | ||

| + | |The sum of the total gas production on the well is used for the water test. When using this method be sure to check that the gas product(s) are either entered or allocated previously. | ||

| + | |- | ||

| + | |B - Check Meter (Site) | ||

| + | |This method uses the sum of all check meters on the target site for the test value. If no check meter volumes exist the process will look for the most recent daily test value. | ||

| + | |- | ||

| + | |C - Check Meter | ||

| + | |This method attempts to locate a check meter volume to use as a test value. If no check meter volume can be found, the process will look for the most recent daily test value. | ||

| + | |- | ||

| + | |J - Oil LACT(M) | ||

| + | |This method is identical to the 'R' method, but it looks at the LACT meter volume instead of the daily test values. | ||

| + | |- | ||

| + | |L - LACT Meter Test | ||

| + | |This method retrieves the calculated LACT meter production and uses it as it's test value. If there is no calculated volume the test value for the day defaults to zero for the allocation. | ||

| + | |- | ||

| + | |O - Gas Yield | ||

| + | |This method calculates the test value by retrieving the most recent test value and the sum of the gas production for the day. It derives the test value using the formula: (TEST/1000) x GASPROD. When using this method ensure that the gas product(s) are either entered or allocated previously. | ||

| + | |- | ||

| + | |P - Hrs x Test w/Fixed Test | ||

| + | |This method is similar to type H, but treats test as mandated volume if site in test for allocation date. | ||

| + | |- | ||

| + | |W - Water Oil Ratio | ||

| + | |The test is determined by resolving the most recent daily water test which is the ratio to use and the total oil production for the day and applying the formula: OILPROD x RATIO. When using this method, you should ensure that the oil production is either entered or allocated prior to the water product. | ||

| + | |- | ||

| + | |X - Water Sum with Source Update | ||

| + | |This method sums up the gross water production on the targets and creates a source record to allow allocation of the combined sales from multiple products. Source product must have 2 water products (SOURCE/SUM). | ||

| + | |- | ||

| + | |Y - Gas Water Ratio with Source Update | ||

| + | |This method derives a test value using a Gas/Water ratio. The ratio used is the most recent daily water test which is multiplied by the sum of the gas production for the day. Once all targets have been allocated the source water record is either created or updated with the sum of all target products in the allocation. | ||

| + | |- | ||

| + | |Z - Water Oil Ratio With Source Update | ||

| + | |This method forces the allocated water production to be determined using an Water/Oil ratio. The WOR ratio used is the most recent test entry for the target. Once all targets have been allocated, the source water production is replaced with the sum of the targets' production. | ||

| + | |- | ||

| + | |4 - Entered Wtr Is Test | ||

| + | |This method retrieves the previously entered water volume for the day as the test. Normally used in when water is populated via a SCADA import. | ||

|- | |- | ||

|} | |} | ||

Latest revision as of 17:24, 21 November 2024

Set up sites and products to be allocated and the order in which the allocation or allocations will be performed.

Contents

Main Allocation Screen

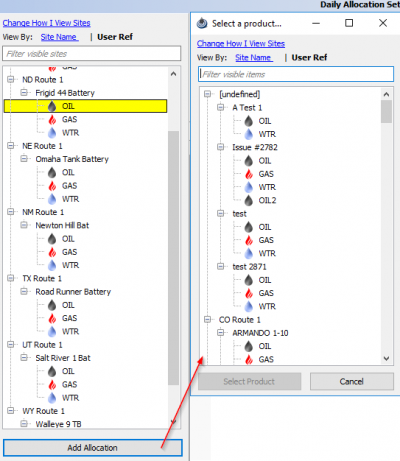

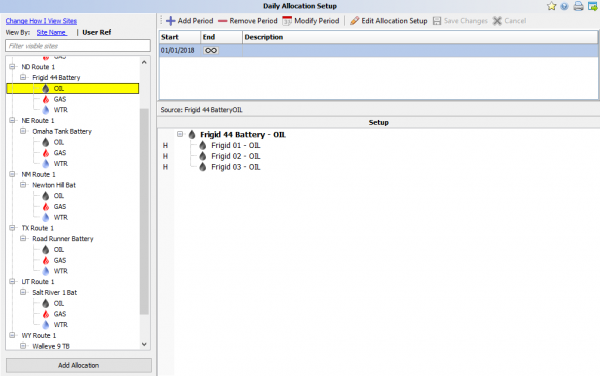

To begin select Daily Processes > Daily allocation Setup, the following screen will open:

|

This screen is almost identical to Monthly Allocation Setup, the difference being the test methods provided per each target. understanding this setup will make setting up the monthly side easier.

To the far left you can see all the allocations that already have setups. If you select one the right side will open up and allow you to view the targets and the tests that reside within it. From this panel, a period can be added, removed or modified. An allocation set up can also be edited in this panel. When an allocation is created first a period holder must be created and this is where the alloc record sits. Multiple periods will show different setups such as wells coming online. If you need to modify a period when something new is happening, make sure to end the current period, thus keeping a history and allowing the allocations in that time frame to still be allocated with that setup. When you add a new period the old targets will roll over and you can add or take away from them. Keeping the end date open the allocation will run as long as you need. If you try to delete out an allocation it will not modify the data but the original setup will be lost. There is a warning screen if it was an accidental click. |

Adding an Allocation.

|

To add an allocation for a product select the "Add Allocation Button". The following screen will appear: |

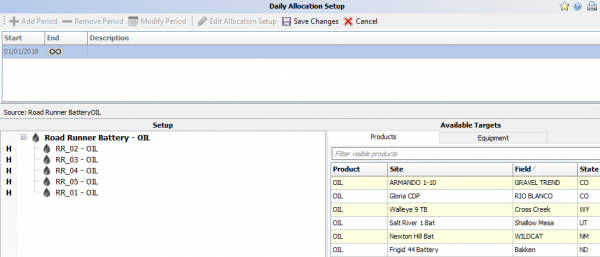

Use the scroll or the filter option to find a site and select a product you want to allocate from. Any product that is in this screen, does not have an allocation yet and is available to allocate. After you select a product you will be prompted to input in a start date and you can also add in a description for the new period. Make sure it matches the other products if they come on at the same time. When the date info has been added then the target selection screen will appear: To add in sites select the site on the right using the filter to find it and click and drag over or double click. Shift and Ctrl select is also allowed here. Next add in a allocation code to determine a Test Derivation Method. A full list can be seen in the next section of this page for reference. A feature of adding in other allocations for a site is that if one product has been added in then the others will be able to automatically fill in the matching targets. You will also be able to do this in monthly allocation setup, this is why is recommended to start your daily first. When all targets have been added in then save your changes. |

Test Methods

In order for you allocation to work it need extra information to go off of based on what test method is used.

Here are the definitions that can be used:

Oil Test

| T - Fixed Ratio | Locates the most recent daily test value and applies it as a fixed ratio within the allocation. This is the most common method used. To learn how to add a daily test click here. |

| H - Hours On X Test | Uses the most recent daily test value and calculates a new value by taking the test value divided by hours on times 24 hours: ((test value/hours on)*24) |

| D - Define Value | A special allocation method that uses whatever value is listed as the entered production for a day is to be kept whole and all other wells in the allocation share whatever production in the source file remains. |

| E - Gas Production | The current day’s gas production is used for the test. When using this method you must make sure that the gas production records exist, either by entry or proper ordering of the products in the allocation. A gas test value will be zero if gas records are absent. |

| 3 - Test is Water Production | The current day's water production is used for the oil test. Requires that water is defined to be allocated prior to oil in source. |

| J - Custody Meter | This method retrieves the sum of the current day and product's oil meters on the well and applies that volume as the allocated volume as long as the sum of this value plus any other products in the allocation that use methods D, J, M or R is less than or equal to the total volume in the source. If the source is less than the total amount it will receive a proportional amount based on it's relative value within the other defined types. Nothing will be allocated if an oil test value is absent. |

| L - LACT Meter | The sum of the oil LACT meters for the current day and product are used as the test value. Zero will be the test value used if oil values are absent. |

| 5 - LACT Meter Minus Load Oil | This method retrieves the calculated LACT meter production and uses it as its base test value. If there is no meter volume the most recent test value is used. The sum of any non-calc oil meters is retrieved and the test is reduced by that amount. |

| O - Gas Yield | This method calculates the test value by retrieving the most recent test value and the sum of the gas production for the day. The Gas Yield method derives the test value using the formula: (TEST/1000) x GASPROD. When using this method be sure to check that the gas product(s) are either entered or allocated previously. |

| P - Hrs x Test w/Fixed Test | This method is similar to type H, but treats test as mandated volume if site in test for allocation date. |

| R - Turbine Meter | This method retrieves the current day's oil test value and applies that volume as the allocated volume as long as the sum of this value plus any other products in the allocation that use methods D, J, M or R is less than or equal to the total volume in the source. If the source is less than the total amount it will receive a proportional amount based on its relative value within the other defined types. Zero will be the test value used if oil values are absent. |

| S - LACT w/CI+Sales | This method is used for battery to pad allocations. Source is allocated using LACT meters then the pad sales and then change in inventory is added back in. |

Gas Test

| T - Fixed Ratio | Locates the most recent daily test value and applies it as a fixed ratio within the allocation. This is the most common method used. To learn how to add a daily test click here. |

| H - Hours On X Test | Uses the most recent daily test value and calculates a new value by taking the test value divided by hours on times 24 hours: ((test value/hours on)*24) |

| D - Define Value | A special allocation method that uses whatever value is listed as the entered production for a day is to be kept whole and all other wells in the allocation share whatever production in the source file remains. |

| A - Hrs x Test w/GL Removed | This method derives the test by first resolving the hours on x test and then removes the gas lift volume from the test prior to allocation. |

| B - Check Meter (Site) | This method uses the sum of all check meters for all gas products on the target site for the test value. If no check meter volumes exist the process will look for the most recent daily test value. |

| C - Check Meter | This method sums the meter volumes on the current product and day where the meter is defined with a disposition type 'Check Meter'. The Check Meter methods will default to using the most recent daily gas test as a fixed ratio if gas records are absent. |

| F - Hours x Test w/Gas Lift Recalculation | This method starts by following the same process as type H but recalculates the production after the allocation is complete by deducting any gas lift. The volume for the gas lift is determined by adding up the meter volumes for the current day and product where the disposition specified is 'Gas Lift'. |

| G - Gas Oil Ratio | The test is determined by resolving the most recent daily gas test which is the ratio to use and the finding the total oil production for the day and applying the formula: OILPROD x RATIO. When using this method ensure that the oil production is either entered or allocated prior to the gas product. |

| I - Check - Lift | This method sums the gas check meters on the site and reduces that amount by the amount of gas lift meter volumes to calculate a volume for the test value. If no check meter values exist the most recent 24 hour test is used. |

| K - Oil Production | The current days oil production is used for the test. When using this method you must ensure that the oil production records exist, either by entry or proper ordering of the products in the allocation. If no oil records are found the test value used will be zero. |

| M - Meter Test | This method retrieves the sum of the current day's gas check meters for the product and applies that volume as the allocated volume as long as the sum of this value plus any other products in the allocation that use methods D, J, M or R is less than or equal to the total volume in the source. If the source is less than the total amount it will receive a proportional amount based on it's relative value within the other defined types. If check meter records do not exists for the current day then it will be allocated zero. |

| N - Gas Lift Test | This method retrieves the sum of active gas lift meters to use as the test value and then removes the gas lift from the allocated gross production after the allocation is complete. |

| P - Hrs x Test w/Fixed Test | This method is similar to type H, but treats test as mandated volume if site in test for allocation date. |

| Q - Metered Gas in Gas Lift Allocation | This method is designed to work explicitly with other products on the well defined as type 'F' to allow wells to be included in the allocation that are only used to reduce the source volume from the return gas meter. It retrieves the sum of the custody meter volumes on the product as the test value. Updates are not made to product records with Metered Gas in Gas Lift Allocation. |

| S - Sum Gas From Targets | If all gas target products use method S then create/update meter and product of source product with the sum of the targets. Source product must have a sales meter. |

| V - Hrs x Test w/Fixed Test (GL) | This method defaults to hours x test unless a test exists for the day, then becomes mandated value. Any gas lift is removed from the test prior to allocation. |

| U - Gas Lift Test | This method retrieves the sum of active gas lift meters to use as the test value. |

| X - Sales Meter Sum with Source Update | This method sums up the sales meters on the targets and creates a source record to allow allocation of the combined sales from multiple products. Source product must have 2 gas products (Sales/Sum). |

| 1 - Hrs x Test - Gas Lift | This method first gets a base test using method H (hours on x test) then removes the sum of the gas lift meters to create the final test to be used. |

| 2 - Check - Buyback | This method derives a test value by reducing the sum of the check meter volume by the sum of the buyback meter volumes. |

Water Test

| T - Fixed Ratio | Locates the most recent daily test value and applies it as a fixed ratio within the allocation. This is the most common method used. To learn how to add a daily test click here. |

| H - Hours On X Test | Uses the most recent daily test value and calculates a new value by taking the test value divided by hours on times 24 hours: ((test value/hours on)*24) |

| D - Define Value | A special allocation method that uses whatever value is listed as the entered production for a day is to be kept whole and all other wells in the allocation share whatever production in the source file remains. |

| E - Gas Production | The sum of the total gas production on the well is used for the water test. When using this method be sure to check that the gas product(s) are either entered or allocated previously. |

| B - Check Meter (Site) | This method uses the sum of all check meters on the target site for the test value. If no check meter volumes exist the process will look for the most recent daily test value. |

| C - Check Meter | This method attempts to locate a check meter volume to use as a test value. If no check meter volume can be found, the process will look for the most recent daily test value. |

| J - Oil LACT(M) | This method is identical to the 'R' method, but it looks at the LACT meter volume instead of the daily test values. |

| L - LACT Meter Test | This method retrieves the calculated LACT meter production and uses it as it's test value. If there is no calculated volume the test value for the day defaults to zero for the allocation. |

| O - Gas Yield | This method calculates the test value by retrieving the most recent test value and the sum of the gas production for the day. It derives the test value using the formula: (TEST/1000) x GASPROD. When using this method ensure that the gas product(s) are either entered or allocated previously. |

| P - Hrs x Test w/Fixed Test | This method is similar to type H, but treats test as mandated volume if site in test for allocation date. |

| W - Water Oil Ratio | The test is determined by resolving the most recent daily water test which is the ratio to use and the total oil production for the day and applying the formula: OILPROD x RATIO. When using this method, you should ensure that the oil production is either entered or allocated prior to the water product. |

| X - Water Sum with Source Update | This method sums up the gross water production on the targets and creates a source record to allow allocation of the combined sales from multiple products. Source product must have 2 water products (SOURCE/SUM). |

| Y - Gas Water Ratio with Source Update | This method derives a test value using a Gas/Water ratio. The ratio used is the most recent daily water test which is multiplied by the sum of the gas production for the day. Once all targets have been allocated the source water record is either created or updated with the sum of all target products in the allocation. |

| Z - Water Oil Ratio With Source Update | This method forces the allocated water production to be determined using an Water/Oil ratio. The WOR ratio used is the most recent test entry for the target. Once all targets have been allocated, the source water production is replaced with the sum of the targets' production. |

| 4 - Entered Wtr Is Test | This method retrieves the previously entered water volume for the day as the test. Normally used in when water is populated via a SCADA import. |